Körber and Sereact Unite to Deliver AI-Driven Robotic Picking for Smart Intralogistics

Körber Supply Chain has officially welcomed AI robotics specialist Sereact into its growing ecosystem, reinforcing its capabilities in smart automation. The strategic collaboration aims to enhance both companies’ presence in the intralogistics sector by integrating AI-powered robotic picking into comprehensive production and distribution solutions.

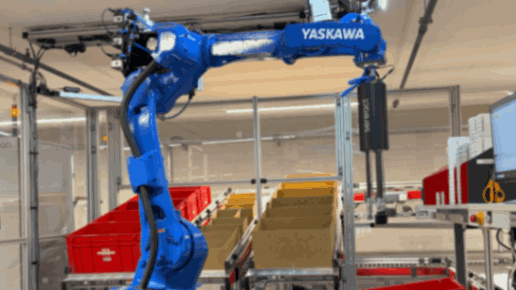

As part of this partnership, Körber now offers Sereact’s cutting-edge AI control software and matching robot hardware as part of its solution suite. The collaboration is already in motion with a flagship joint project underway with a prominent German mechanical engineering firm.

By embedding intelligent single-item picking into end-to-end workflows, businesses can directly address key challenges such as labor shortages, rising error rates, and the need for faster fulfillment times. At the heart of the system is Sereact’s advanced gripping software, capable of handling a wide variety of products—including those it has never encountered before—thanks to sophisticated AI algorithms.

Success in robotic picking relies heavily on seamless process integration and a deep understanding of customer operations. Körber, a leading systems integrator, ensures that Sereact’s robotic solutions are implemented with precision—from initial consulting to deployment—delivering real-world value and efficiency. The result: reduced reliance on manual labor, greater adaptability to throughput fluctuations, and a more resilient supply chain.

Sereact’s proprietary technology combines state-of-the-art generative AI, low-level robotics, and innovative hardware. The system leverages imitation and reinforcement learning, along with a powerful vision-language model that interprets product names, descriptions, and contextual text to accurately identify and localize items in real time.

Each deployment is custom-designed, beginning with an analysis of which items can be picked, defining workflows such as “pick-and-place,” and ensuring the system meets required throughput goals. Körber and Sereact work side by side to tailor each solution to the customer’s unique needs.

Körber’s Supply Chain division continues to expand its portfolio of scalable, fully integrated automation solutions through collaborations with technology innovators. The addition of Sereact strengthens Körber’s role as a leading robotics integrator within the global supply chain landscape.

“In today’s fast-paced market, staying competitive requires flexible and scalable automation,” said Michiel Veenman, Vice President Advanced Technology Integration at Körber Supply Chain Automation. “With Sereact’s best-in-class AI technology, we can now offer advanced robotic single-item picking that integrates seamlessly into our customers’ operations.”

Together, Körber and Sereact are shaping the future of intralogistics—one intelligent robot at a time.